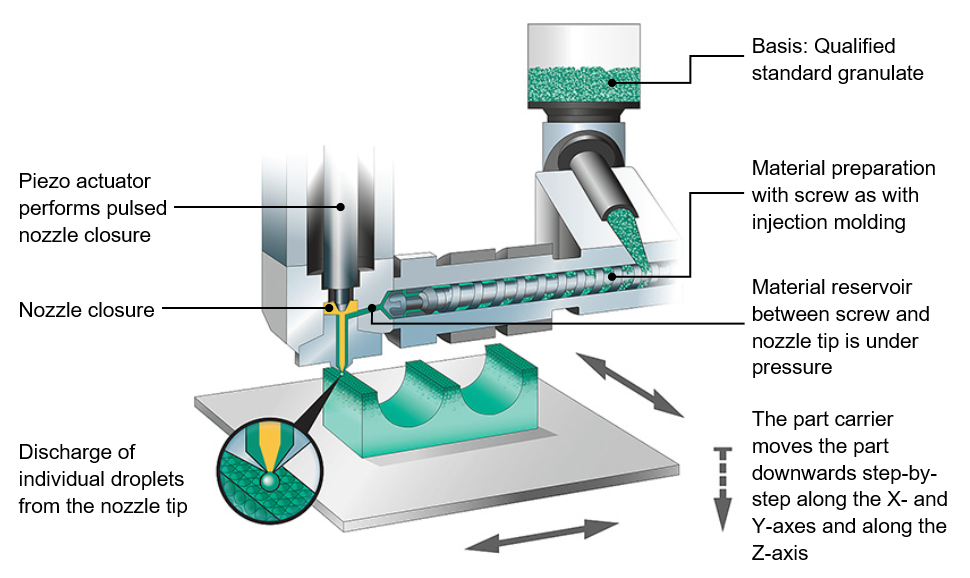

ARBURG Plastic Freeforming (APF)

ARBURG Plastic Freeforming (APF) is an additive manufacturing process to produce thermoplastic components. This manufacturing process has been developed by ARBURG GmbH + Co KG and enables the production of three-dimensional objects out of qualified standard granulate. In 2015, the market launch of the freeformer, a machine developed for the APF process, took place.

The freeformer is equipped with two plasticizing and discharge units as standard. For this reason, two individual components or colors can be processed simultaneously. This makes it possible to realize hard/soft combinations or colored parts, for example. Furthermore, a special water-soluble material can be used.

Principle of Layer Generation

First of all standard granulates are melted as in the injection moulding process. After that the molten material is pressed with an axial movement of the plasticizing screw in the discharge unit. A piezoeletric high frequency nozzle closure generates with rapid opening and closing movements up to 200 tiny droplets of plastic per second with a diameter between 0.2 and 0.4 mm.

Moreover the precise positioning of the plastic droplets on previously calculated points is realised by a movable three-axis part carrier. The plasticizing and the discharge unit are stationary machine elements.

The placed plastic droplets are bonded with the hardened material as they cool down, so diverse three-dimensional plastic parts are build layer by layer.

Build Chamber Volume

The dimensions of the usable build chamber are 230 x 135 x 250 (h x w x d) and the maximal part weight is limited up to 1500 g. In addition, the freeformer is equipped with a heated build chamber (50 – 100 °C).

Build Time and Build-up Rate

The build time and build-up rate depend on the part geometry, the material, the used nozzle as well as the process parameters. In regard to the parameters, the layer thickness and the traverse speed has to be considered. Generally, the discharge quantity depending on the nozzle size is between 5 and 21 cm3/h.

Surface Quality and Accuracy

With an increasing layer thickness and plastic droplet size, the surface quality is decreasing. Using different nozzle sizes the freeformer generates layer thicknesses between 200 and 320 µm.

ARBURG specified the part accuracy with ± 0.15 mm for using ABS. For the surface quality, the roughness value Ra is listed around 20 µm. The minimal wall thickness varies between 0.6 and 1.0 mm depending on the nozzle size.

Material

So far, the materials ABS, PC, PA12 (amorphous) and TPU are specified for the freeformer. Besides that, the range of materials will be constantly extended to get more qualified standard granulates such as PP for the process.

The open machine control enables the users to vary all the process parameters in consideration of the machine limits, whereby the maximum temperature is 300 °C. Consequently, this system opens up the possibility to use other thermoplastic materials as well.

In the case of complex part geometries, a water-soluble support material based on polyvinylpyrolidon is used.

Post-Processing

In general there is no post processing required. If support material was used, it has to be removed. Machining/sanding can be applied to reduce surface roughness.

Build Materials

Specified:

ABS

PC

PA12 (amorphous)

TPU

... In principle, all thermoplastics!

Technical Data

ARBURG freeformer

Building dimensions: 230 x 135 x 250 mm (H x W x D)

Support structures: necessary / water-soluble

Building speed: material and parameter dependent

Layer thickness: 0,20 - 0,32 mm (material dependent)